The M109A6 Paladin is the latest advancement in 155mm self-propelled artillery. The system

enhances previous versions of the M109 by implementing onboard navigational and

automatic fire control systems. Paladin has both a Kevlar-lined chassis and a pressurized

crew compartment to guard against ballistic, nuclear, biological, and chemical threats.

The M109A6 Paladin is the latest advancement in 155mm self-propelled artillery. The system

enhances previous versions of the M109 by implementing onboard navigational and

automatic fire control systems. Paladin has both a Kevlar-lined chassis and a pressurized

crew compartment to guard against ballistic, nuclear, biological, and chemical threats.

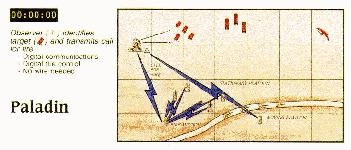

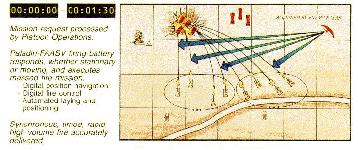

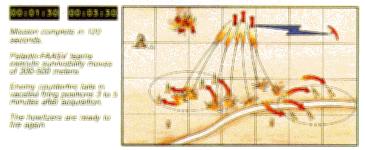

The M109A6 is the most technologically advanced cannon in the Army inventory. This weapon has a 4 man crew, and weights approximately 62,000 lbs/32 tons, and has a cruising range of 186 miles, Max speed is 35 MPH, It has a fuel capacity of 133 gals. The Paladin can operate independently, from on the move, it can receive a fire mission, compute firing data, select and take up its firing position, automatically unlock and point its cannon, fire and move out - all with no external technical assistance. Firing the first round from the move in under 60 seconds, a "shoot and scoot" capability protects the crew from counterbattery fire. The M109A6 Paladin is capable of firing up to four rounds per minute to ranges of 30 kilometers. The Paladin features increased survivability characteristics such as day/night operability, NBC protection with climate control and secure voice and digital communications. The crew remains in the vehicle throughout the mission.

The Paladin is designed to accept new technologies increasing firing range, rate of fire, and accuracy. TACOM-ARDEC, in order to maintain the state-of-the-art in artillery technologies, is continuing to develop enhancements adaptable to Paladin, such as a 52 caliber gun, Modular Artillery Charge System (MACS), and a laser ignition system. The Paladin/FAASV program entails a major product improvement and re-engineering effort - begun in 1979 - to upgrade the U.S. Army's primary self-propelled long-range howitzer, designated the M109 series. Range, lethality, reliability, speed and mobility were all limitations of this 1950's design, as was the lack of onboard navigation/location and nuclear, biological and chemical protection for the crew. The new Paladin closes the technology gap in response to the requirements of the U.S. Army Soldier. These "shoot and scoot" requirements, were translated into engineering requirements and specifications that updated or replaced every subsystem of the vehicle.

By the end of 1999, 824 Paladins will be in the hands of US Army and National Guard Field Artillery units in accordance with a detailed schedule that includes advance Materiel Fielding Team customer familiarization, new equipment training for both officers and enlisted personnel, and all of

the associated logistics, spares, manuals, trainers and testing devices for the weapons system.

The Letterkenny Army Depot is a key partner with the Defense Depot Letterkenny, PA (DDLP) in ensuring availability of the 1900 necessary parts to the production line. Letterkenny Army Depot's partnership role is to deprocess old howitzers, salvage reusable chassis and components and integrate all chassis/automotive upgrades into the refurbished Paladin chassis. United Defense Limited Partnership Paladin Production Division, also collocated at Letterkenny Army Depot

forms part of the production line, applying its skills in systems and turret integration after receiving the Paladin chassis from Letterkenny. The Defense Contract Management (DCM) partner is the designated Department of Defense in-plant organization to ensure both product quality and fiscal integrity of the defense contractor, United Defense Limited Partnership. Major suppliers include Honeywell (navigation/positioning systems), Detroit Diesel (new low heat rejection

engines), United Defense - Ground Systems Division (turret manufacturer), Watervliet Arsenal (cannons and ballistic shielding) and Alliant Tech Systems (Automatic Fire Control System).

Life cycle sustainment support for the M109 FOV is currently provided by multiple government and commercial organizations using many different processes to deliver both services and materials. Duplicative infrastructure and processes are common. Engineering/technical support is performed by multiple contractors and Army commands. Maintenance, overhaul, and repair is achieved through a complicated structure of organic shops that depend on the commercial sector for parts and other government agencies for technical guidance and funding. The production contractor and government supply system acquire and provide parts for initial provisioning, production, modification, repair (field and depot), overhaul, and war reserves. The current support infrastructure limits opportunity for a coordinated effort to achieve cost reduction, implement best business practices, improve weapon system performance, and modernize equipment. Accountability is widely dispersed. By the end of 1999 the US Army TACOM-ARDEC Acquisition Center and the Product Manager for Paladin/FAASV intends to issue a contract for a Fleet Managemer for the M109 Family of Vehicles (FOV). The Fleet Manager (FM) will be the single world class focal point for the M109 FOV life-cycle sustainment support, to include supply, engineering and limited life cycle support functions by having one point of contact and focal point for all M109 FOV life-cycle program management and weapon system support. The Pilot Program critical objective is to validate 20-30% sustainment savings .

The Paladin/FAASV program entails a major product improvement and re-engineering effort - begun in 1979 - to upgrade the U.S. Army's primary self-propelled long-range howitzer, designated the M109 series. Range, lethality, reliability, speed and mobility were all limitations of this 1950's design, as was the lack of onboard navigation/location and nuclear, biological and chemical protection for the crew. The new Paladin closes the technology gap in response to the requirements of the U.S. Army Soldier. These "shoot and scoot" requirements, were translated into engineering requirements and specifications that updated or replaced every subsystem of the vehicle.

By the end of 1999, 824 Paladins will be in the hands of US Army and National Guard Field Artillery units in accordance with a detailed schedule that includes advance Materiel Fielding Team customer familiarization, new equipment training for both officers and enlisted personnel, and all of

the associated logistics, spares, manuals, trainers and testing devices for the weapons system.

The Letterkenny Army Depot is a key partner with the Defense Depot Letterkenny, PA (DDLP) in ensuring availability of the 1900 necessary parts to the production line. Letterkenny Army Depot's partnership role is to deprocess old howitzers, salvage reusable chassis and components and integrate all chassis/automotive upgrades into the refurbished Paladin chassis. United Defense Limited Partnership Paladin Production Division, also collocated at Letterkenny Army Depot

forms part of the production line, applying its skills in systems and turret integration after receiving the Paladin chassis from Letterkenny. The Defense Contract Management (DCM) partner is the designated Department of Defense in-plant organization to ensure both product quality and fiscal integrity of the defense contractor, United Defense Limited Partnership. Major suppliers include Honeywell (navigation/positioning systems), Detroit Diesel (new low heat rejection

engines), United Defense - Ground Systems Division (turret manufacturer), Watervliet Arsenal (cannons and ballistic shielding) and Alliant Tech Systems (Automatic Fire Control System).

Life cycle sustainment support for the M109 FOV is currently provided by multiple government and commercial organizations using many different processes to deliver both services and materials. Duplicative infrastructure and processes are common. Engineering/technical support is performed by multiple contractors and Army commands. Maintenance, overhaul, and repair is achieved through a complicated structure of organic shops that depend on the commercial sector for parts and other government agencies for technical guidance and funding. The production contractor and government supply system acquire and provide parts for initial provisioning, production, modification, repair (field and depot), overhaul, and war reserves. The current support infrastructure limits opportunity for a coordinated effort to achieve cost reduction, implement best business practices, improve weapon system performance, and modernize equipment. Accountability is widely dispersed. By the end of 1999 the US Army TACOM-ARDEC Acquisition Center and the Product Manager for Paladin/FAASV intends to issue a contract for a Fleet Managemer for the M109 Family of Vehicles (FOV). The Fleet Manager (FM) will be the single world class focal point for the M109 FOV life-cycle sustainment support, to include supply, engineering and limited life cycle support functions by having one point of contact and focal point for all M109 FOV life-cycle program management and weapon system support. The Pilot Program critical objective is to validate 20-30% sustainment savings .