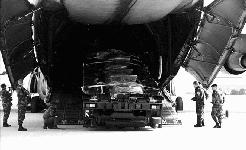

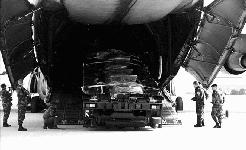

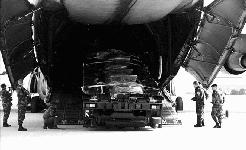

60k Tunner Material Handling Equipment (MHE)

The new 60k Tunner loader has a total loading capacity of 60,000 pounds. It will replace older, 40,000-pound capacity loaders in the Air Force inventory. The Tunner can carry up to six cargo pallets at once, drive on and off C-5, C-17 and C-141 aircraft, and load and unload cargo from all military and commercial cargo aircraft. Other advantages of the new loader include an improved turning radius, higher top speed and mechanized rollers that greatly enhance the loading and unloading

process. The Tunner is much better than its predecessors�so far five times more reliable and 150 to 350 percent more capable.

Prior to the Tunner, loading and unloading wide-body aircraft required special equipment only capable of raising or lowering cargo two or three pallets at a time. A 25,000-pound loader or a 40,000-pound loader was still required to transport the pallets to and from the

aircraft. The Tunner Loader, which transports and loads, eliminates this need for an additional piece of equipment.

The loader has a

payload capacity of 60,000 pounds � 20,000

pounds more than the 40K loader. This will

have a major impact when loading large and

heavy cargo, especially when airlifting

tractor-trailers exceed the capability of a 40K

loader. Currently, it would take 20 to 30

minutes to prepare to load these items on a

C-5. Specialized loading equipment such as

wooden planks are required to prevent the

trailer from coming in contact with the ramp of

the aircraft when the tractor trailer is driven

onto the C-5. In contrast, the tractor-trailer

can be loaded straight from the Tunner to the

aircraft.

The Tunner Loader has a roll-on, roll-off

capability that makes it easy to be transported

to where it is needed. It requires no

reconfiguration for transport on a C-5 or C-17

and can be reconfigured for transport on a

C-141 in 90 minutes by three people. Unlike

the 40K which takes two people more than

three hours to prepare. Upon arrival at any

destination, the Tunner is immediately ready to

perform its mission.

The loader has a versatile deck that elevates

from 39 inches to 18.5 feet and a powered

conveyer system to move cargo. With other

equipment, several people are required to push

pallets into position.

The deck has pitch roll, yaw and a side-to-side

adjustment for quick interface with all military

and commercial cargo aircraft. It can be driven

up to an aircraft, adjust to the correct height

and use its conveyer system to unload cargo.

When the cargo is unloaded the Tunner Loader

can be driven to another aircraft, adjust to its

height and use the conveyer system to load it.

It provides a seamless transfer of cargo.

A name-the-60k contest voted to call it the Tunner, after General William H. Tunner who directed the Burma Hump, Korean, and Berlin Airlifts.

The first Tunners were delivered in the summer of 1997 to Ramstein and Dover. Twenty-five Tunners were delivered by the contractor, accepted by the government and operational for 60 days as of 18 August 1998. The Tunner reached initial operational capability on 06 November 1998. IOC is declared when the initial operational test and evaluation is successfully completed, all technical data is available, initial operator and maintenance training is complete, spare parts are available, and when the low rate initial production units have been delivered, accepted and operational for 60 days.

The new loader is built by Systems & Electronics, Inc., in West Plains, Mo. The Air Force currently has 37 Tunner loaders at 15 bases worldwide, plus one prototype for maintenance training. The Air Force is currently committed to procuring 103 Tunners from SEI, with additional buys to be negotiated annually.

Sources and Resources

http://www.fas.org/man/dod-101/sys/ac/equip/tunner.htm

Maintained by Robert Sherman

Originally created by John Pike

Updated Tuesday, February 15, 2000 10:35:15 AM